The direct shear test is a simple lab tests that measure how strong soil is. It measures the soil’s capacity for resisting sliding or failing under the pressure of forces. Engineers can utilize this test to evaluate soils. It is done for establishing building foundations slopes and retaining walls.

The test can save them a lot of money from not having to pay for expensive repairs.

The direct shear test is a relatively straightforward test in geotechnical engineering. It is very useful to the construction industry as it is simple and dependable. Moreover, engineers depend on the direct shear test to reassure buildings are built safely.

What Is the Direct Shear Test?

A direct shear test is a laboratory test to determine the shear strength of soil. A direct shear test produces two values, cohesion (c) and the angle of internal friction (ϕ). These two values provide engineers valuable information about soil behavior under pressure forces.

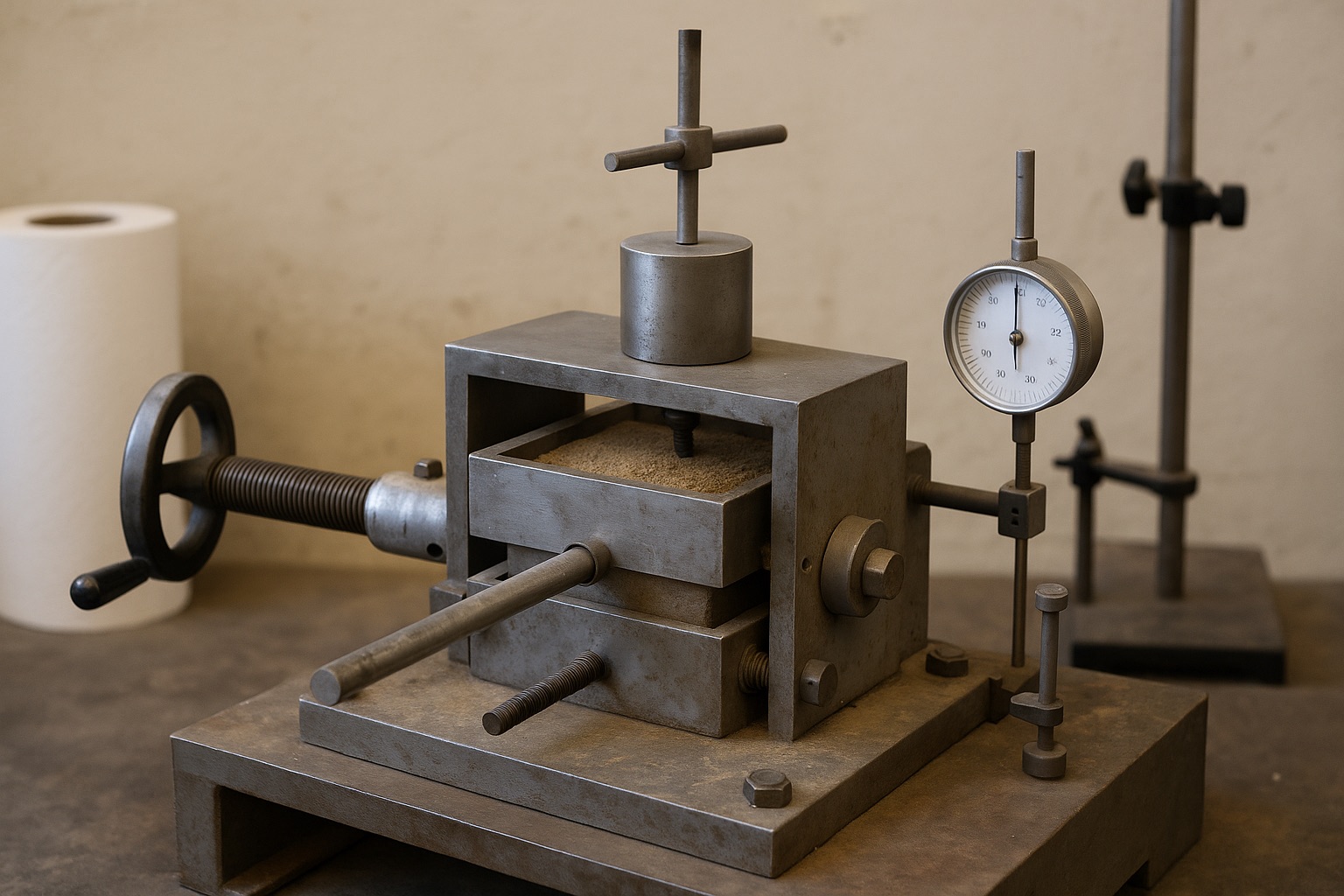

The direct shear test uses a device known as a direct shear box. Soil is placed inside the box and divided into two halves. A horizontal force is applied to one half while normal stress presses down on the soil. This setup simulates the soil sliding or failing in real conditions.

During a direct shear test, the engineer applies a load to the soil. He monitors the force at which the soil will shear. These measurements represent the load the soil can take before sliding then failing. This is all critically important for the geotechnical designs. Engineers rely on this test to ensure safe and stable construction on soil.

Purpose of the Direct Shear Test

The direct shear test helps engineers see how soil resists sliding. It illustrates the strength of soil along a potential failure plane. This is important because poor soil condition can create large surface failure at a site.

Engineers utilize the results in a variety of ways for proper geotechnical designs.. Understanding the soil strength provides the engineer with a basis to establish reinforcement.

The test also helps calculate safety factors for construction projects. These factors ensure that the soil can handle extra loads or unexpected stress.

Using the direct shear test results makes construction safer and more reliable.

Apparatus Used in the Test

The direct shear test uses a special box called a direct shear box. This box is split into an upper and lower half. The soil sample is placed inside, and the box allows the top half to move while the bottom stays fixed.

To measure force, a proving ring or load cell is used. This tells how much shear force the soil can resist. Micrometer gauges or dial gauges measure how much the soil moves during the test.

Weights are added on top to apply normal stress. A shear force actuator—either motorized or manual—applies horizontal force to slide the soil. Typical soil specimens are small block sizes approximately 60 mm x 60 mm x 25 mm.

Read more to find out Why Every building, bridge, or roadway must follow strict codes.

Direct shear test apparatus with soil sample in place, ready for laboratory testing of shear strength.

Procedure: Step-by-Step Test Method

First, the soil sample is prepared. It can be undisturbed from the field or remolded in the lab. The sample is carefully placed into the direct shear box so it fits snugly and evenly. In Southern California Los Angeles Department of Building and Safety provides guidelines for geotechnical preparation.

Next, a normal load is applied on the soil. This simulates the weight of soil above or a structural load on top. For saturated soils, the sample may be allowed to consolidate under the load. This lets water drain slowly and gives more realistic results.

The shearing step comes after preparation. The upper half of the box is moved sideways at a constant speed. This lateral movement causes the soil to resist sliding, and the soil will eventually fail along a shear plane.

During the test, data is carefully recorded. Shear force and horizontal displacement are measured. It also measures any vertical movement of the soil. The test is repeated with different normal loads. The final results of the tests are presented in graph form. The graph provides a Mohr-Coulomb failure envelope. This envelop will indicate the cohesion and internal friction of the soil. This helps engineers to design safe slopes, retaining walls and foundations.

Test Conditions and Types

The direct shear test can be done under drained or undrained conditions. In a drained test, water in the soil is allowed to escape. This makes the test slower but gives more accurate shear strength values for soils like sand. In California, drained tests for sandy soils are often performed. It is in accordance with California Geological Survey recommendations and local geotechnical requirements. These requirements are set by agencies such as LADBS.

In an undrained test, water is not allowed to drain. While the test is quicker, it doesn’t measure pore water pressures. This technique may be used for clay soils, but you would be better off with a triaxial test to get precise results. such as Los Angeles County Public Works.

Soil type affects which method is chosen. Sandy soils need drained tests to avoid excess pore pressure. Clay soils can be tested undrained if speed is important. But engineers must be cautious about the results.

Tests are often repeated using single or multiple specimens. Testing multiple specimens at differing normal loads allows to create a failure envelope. That envelope will illustrate the soil’s cohesion and friction angle. These are important to design for foundations, slopes and retaining structures.

Analysis and Interpretation of Results

At the end of the test, the shear stress is calculated by dividing the shear force recorded by the area of the soil sample. This indicates the force the soil can resist just before the onset of sliding of the soil structure.

A graph of shear stress vs. normal stress is drawn. The intercept of the line indicates the cohesion of the soil (c) and the slope indicates the friction angle (ϕ). These two parameters provide the basis for the Mohr-Coulomb failure equation.

: τ = c + σ tan(ϕ),

It assists engineers in the design of foundations, slopes, and earth retaining structures. It is also given in the LADBS and Caltrans geotechnical manuals.

The test also shows stress-strain behavior. Some soils attain peak strength and then soften to a residual strength. It is important to know both values, especially with clay or other layered soils.

Advantages and Limitations of the Direct Shear Test

Overall, the test certainly is useful for a basic assessment of soil strength. However, engineers need to appreciate the limitations of the test. They must use it when appropriate.

For Southern California projects Los Angeles Department of Building and Safety (LADBS) and Los Angeles County Public Works to ensure compliance with local geotechnical standards.

Advantages

- The direct shear test is simple and fast.

- The test is quite cost effective and easy to perform in most laboratory environments.

- The results are easy to interpret. That is one of the reasons this is a popular test for coarse-grained soils such as sand and gravel.

- However, there are limitations. The test only shears the soil along a predetermined plane. It may not match the soil’s natural failure path.

Limitations

- The test is less accurate for clay or cohesive soils. It doesn’t give suitable results in complicated loading conditions.

- Another limitation of the test is that the test does not measure pore water pressure. However, it is an important consideration for maximum designs.

Applications in Geotechnical Engineering

The direct shear test is used to check retaining walls. Engineers use it to see if the soil can resist sliding. It helps make sure walls stay stable under pressure.

It is also useful for shallow footings. The test shows the soil’s bearing capacity. This helps prevent settlement or uneven floors in buildings.

Another application is sloping stability. The test helps engineers design safe slopes and embankments. It can also evaluate backfill and sub grade soils before paving or construction.

Often, the direct shear test is a preliminary check. It gives a quick estimate of soil strength. Later, engineers may perform more detailed tests for final designs.

Conclusion

The direct shear test is important for understanding soil strength. It demonstrates the resistance of soil to sliding or sloughing. It is important to engineers for planning of safe structures. Shear strength knowledge maintains stability of structures, slopes, and retaining walls.

Picard Shear tests can be simple and cheap. It is widely used for civil engineering and geotechnical engineering projects. The use of whichever method will assist in the design of a safe and cost-effective foundation, slope and/or embankment.

While very useful, the direct shear test works best alongside other tests. Triaxial tests can provide further soil data to assess the shear strength.

FAQ

Q1: What is the purpose of the direct shear test?

The direct shear test yields a soil’s shear strength parameter (the cohesion and the angle of internal friction).

Q2: What types of soils are suitable for the direct shear test?

It is best for particular soils of coarse grain size such as sandy soils or gravel. It can be used for clays; however, the triaxial test is usually the preferred test for cohesive soils.

Q3: What is the difference between drained and undrained tests?

Drained tests allow for the pore water to escape during shearing in steeps. Undrained tests, the pore water cannot escape when shearing, is quicker but may be less accurate for pore pressure.

Q4: How is shear stress calculated in this test?

Shear stress is calculated by dividing the measured shear force by the area of the soil sample in the shear box.

Q5: What are the limitations of the direct shear test?

It uses a predetermined failure plane that may not represent natural failure conditions. It cannot measure pore pressure. This test is less suitable for soils with complex load responses.

Build with knowledge. Build with confidence. Build smart from the ground up.